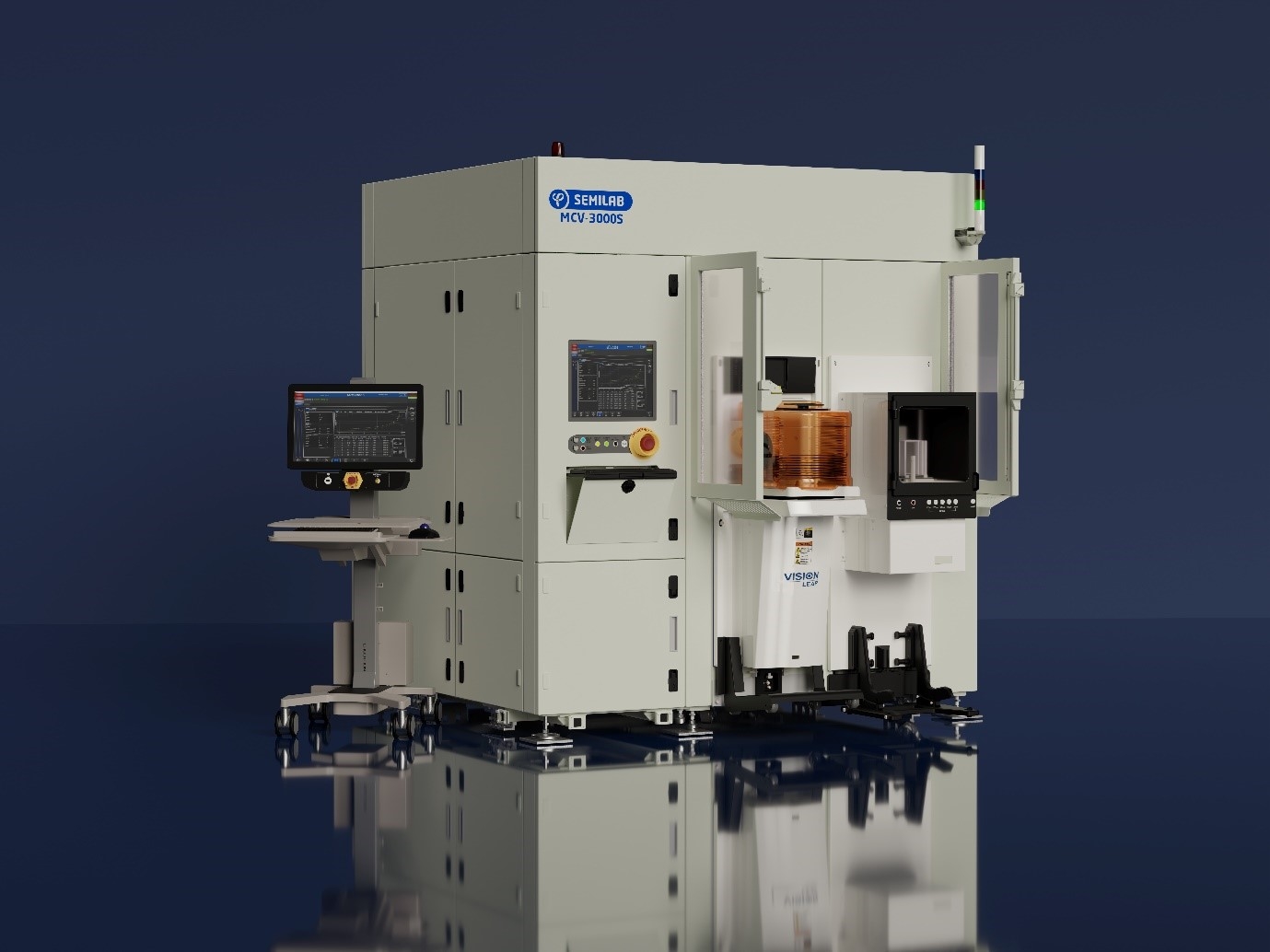

MCV-3000S Facedown Mercury C-V Metrology System

Our innovative MCV-3000S system is configured with Semilab’s new self-aligning probe head design allowing more accurate epitaxial layer characterization on a wide variety of materials up to 300 mm sample sizes, less dependence on sample properties and easier overall maintenance for Si wafermakers.

Semilab MCV-3000S metrology system uses a novel measurement technique. As a result of the fully renewed measurement chamber design the system become capable of accurate characterization of samples with insulating or semi-insulating substrates and samples with a P/N junction, in addition to the capabilities of original MCV tools.

The system is designed to adapt perfectly for fully automated wafer handling of samples up to 300 mm diameter and is equipped with dual load ports that support feed-dump wafer flow, making it ideal for high volume front-end semiconductor production process monitoring. The system’s mini environment provides stable measurement conditions.

Applications

Semilab’s Mercury-contact C-V metrology system is a highly advanced and versatile tool designed for accurate and precise doping and resistivity (valid only for Si) profiling of epitaxial layer structures on bare substrates and characterization of dielectric layers and dielectric-semiconductor interfaces.

Key advantages

- Self-aligning probe head resulting in easier overall maintenance

- Extremely stable Hg return contact supporting measurements to be less dependent on substrate properties resulting in improved measurement accuracy

- Improved tool-to-tool matching

- Only a small quantity of Mercury is used to perform higher level of safety

- Capable of measurement of wide variety of materials - including compound semiconductors

Specifications

- Dual mercury top surface contact design, where both the measurement site and the return contact are formed via mercury on the top surface of the sample

- Wafer flipping mechanism (within the measurement chamber)

- Built-in high-precision Mercury Vapour Monitor

- Mini environment with ULPA filter fan unit(s)

- Full factory automation:

- E84 and OHT capabilities

- FOUP compatible Front-End with dual load-ports

- Automated wafer handling for 300 mm (12”) full sheet wafer samples

- Automated wafer handling for 100-200 mm (4” to 12”) full sheet wafer samples, using adapter plate(s)

- Feed-dump wafer flow is supported

- Pre-Aligner is included

- Wafer ID reader (top, bottom, or both)

Options

- Additional high-precision Mercury Vapour Monitor option

- 3 different reference samples

- Alternative third-party C-V meter options, suitable for multi-frequency measurement

- Wafer Preface Treatment Chamber (PTC) for rapid wafer treatment of full sheet wafer samples

- Wafer ID reader options